The Institute for Hydraulic Engineering and Hydrometry operated the only calibration facility for hydrometric velocity measuring devices (called current meters) in Austria, located in Vienna. The calibration of these devices provided an important basis for the hydrography of our country.

WHY ARE CURRENT METERS NEEDED?

Current meters measure the flow velocity of liquids. The determined flow velocities are primarily used in practice to calculate flow rates. These measuring devices are thus the basis of quantitative hydrography and serve for the design of flood protection structures, the creation of hazard zone plans, and much more.

Flow velocity measurements have significant impacts on:

- Flood protection measures with corresponding effects on risk potential or investment costs

- Discharge surveys for determining the water cycle within the framework of hydrography laws

- Measurements of velocity distributions in pipeline systems and hydropower plants

- Flow rate determinations in industrial facilities (e.g., wastewater flow measurements)

- Scientific research, such as the analysis of pollutant dispersion processes in flowing waters, simultaneous flow measurements for investigating the interaction between groundwater and surface water, relationships between flow velocity and the growth of submerged plants, analysis of the functionality of fish passes for different fish species.

WHAT TYPES OF CURRENT METERS ARE THERE?

Current meters are distinguished by their measurement method. In the past, almost exclusively propeller type current meters were used. These consist of a rotor body and a propeller referred to as a cup. The measurement principle is based on the fact that the flowing water causes the cup attached to the rotor body to rotate. The velocity of the flowing water can be determined based on the number of rotations per unit of time. Currently, there are many devices on the market that measure velocity using ultrasound or a magnetic field.

WHY DO THE MEASURING DEVICES REQUIRE CALIBRATION?

Reliable and comparable water data are necessary for water management. The comparability of measurement data can only be ensured through the use of calibrated measuring devices.

At the calibration facility, a clear relationship between actual velocity and the display of the measuring device is determined through the calibration of these devices. The calibration facility provides the reference velocity as the reference standard for current meters. To enable worldwide comparability of all measurement data, the reference velocity must be traceable to international standards. This is ensured through regular verification of the reference standard by the Federal Office of Metrology and Surveying.

The calibration of a current meter is only valid for a limited time because the calibration relationships can change over time, for example, due to wear and tear of the device. Therefore, recalibration is necessary at regular intervals, as required by many standards worldwide.

HOW TO PERFORM CALIBRATION?

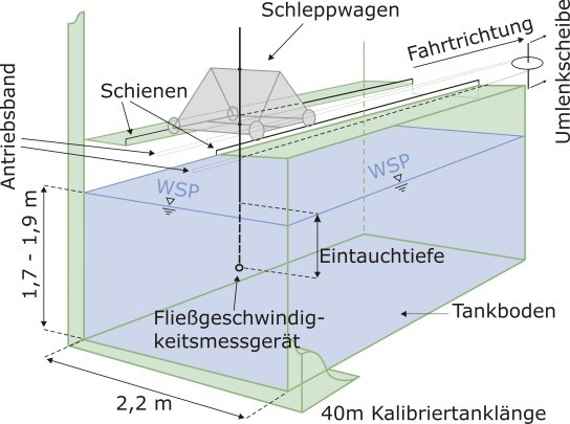

The relationship between the display of the measuring device and the actual flow velocity is determined. A towing carriage (see image) is used to simulate the flow velocity of the water. The current meter is mounted on the towing carriage and pulled through the still water of the calibration tank. The towing carriage speed is set, and the response of the current meter (such as the number of propeller rotations) is recorded. By comparing the towing carriage speed and the response of the measuring device, a calibration relationship can be determined. Using the calibration relationship, the values displayed by the current meter can be converted into actual flow velocities.

At the Institute of Hydraulic Engineering and Hydrometry, the calibration facility operated a calibration tank measuring 40 m in length, 2.2 m in width, and 1.7 to 1.9 m in water depth, a towing carriage with continuously adjustable speed up to 3.4 m/s, and a data acquisition system.

EXAMPLE OF CALIBRATING A PROPELLER TYPE CURRENT METER

- Mounting the current meter on the towing carriage.

- Conducting multiple measurement runs at different towing speeds – the velocity range of the measurement system extends from 0.02 m/s to 3.4 m/s.

- Recording the number of propeller rotations per second at each towing speed.

- Comparing the number of propeller rotations per second with the corresponding towing speed.

- Determining the calibration function.

- Providing the calibration function, along with the quality of the fit, in a calibration certificate to the owner of the measuring device.

The propeller of a current meter rotates in the calibration facility of the Institute of Hydraulic Engineering and Hydrometry in Vienna.

QUALITY MANAGEMENT AT THE CALIBRATION FACILITY

The calibration facility in Severingasse, located in the 9th district of Vienna, was an accredited Austrian calibration service. From May 11, 2000, to May 16, 2023, calibration in the velocity range of 0.02 m/s to 3.4 m/s was accredited according to EN ISO 17025.

Accreditation means that an external body assesses the entire quality management system, including all relevant documentation and work processes, for compliance with the standards. Only with valid accreditation is it permitted to issue calibration certificates with the official logo of the accredited calibration service. The continuous quality management associated with accreditation ensures consistently high-quality calibration activities.